Super Soundproofing Sheet

Overview

|

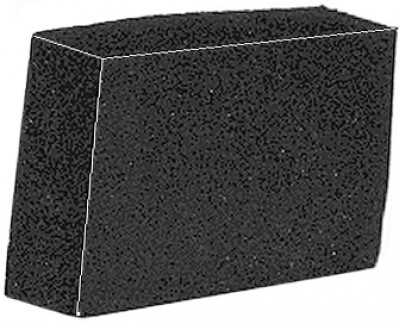

**Note: this material is priced and sold per foot.** This material is excellent for reducing noise levels in all types of certificated and home built aircraft. It is a closed cell vinyl insulating material which will not absorb water or oil. Has fire retardant qualities and meets FAR 25.853a Appendix F, Pt1. It is smooth on one side for easy attachment to the inside cabin skins, sides, top and front firewall. Excellent for helicopters as well. Furnished in bulk 48" wide sheet, it is easily cut by scissors and attached with contact cement. Available in black only. Complimentary Accessory: "How to Soundproof Light Aircraft" Supplement. To order this, simply add part number 09-42755 to your order. |

Specifications Chart

- Size Chart:

Thickness (inches) Weight per Linear Ft 1/8 .25 lbs. 1/4 .60 lbs. 3/8 .80 lbs. 1/2 1.0 lbs. 3/4 1.4 lbs. 1 2.0 lbs. 2 4.0 lbs.

Documents

Reviews

I used 1/4 without adhesive for the underlayment for re-carpeting my C-150. It is working fine. The thickness is perhaps a little more than the quarter-inch I expected.

SUPER SOUNDPROOFING 1/4" BLACK

I ordered a large amount of this material. Aircraft Spruce did a great job packaging the material and the shipment time was incredibly fast for a bulk item. The material was easy to work with and install.

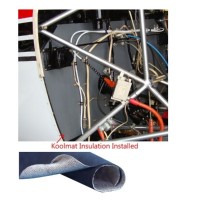

This material seems terrific for insulation my Vans RV-7A experimental airplane. Im installing it now on the floor of cargo area and under seats. I cut it just slightly over size and smash it in. Im not glueing. Fills the gaps nicely. Seems like it will offer both Sound and temperature benefits. Doesnt weigh much. Im using 1 inch which stays under places where I mounted wires.

I had to service/replace some of the ceiling panels in my 1975 Commander so decided to soundproof while I was there. The early Commanders just had 1 fiberglass batts installed throughout most of the plane and these are acoustically useless. I removed them and cleaned the underlying surface with lacquer thinner to give a good surface for new adhesive. I selected the 1/2 thickness for the ceiling/sides based upon the weight and also because most of the stringers in the Commander are 1 or larger so this left easy access for running the existing antenna and power cabling on top of the insulation. This was easy to cut with scissors. I used the old removed pieces of fiberglass as rough templates. For the aircraft sides and ceiling I slightly oversized so that the pieces would hold into place during a test fit then applied 3M 90 contact adhesive to all corners then every about every 6 inches. For the rear plastic bulkhead parts, I removed the old fiberglass, cleaned the surface and repaired old holes/cracks, then applied this soundproofing to the rear of the pieces with plenty of contact cement. Sounds reduction is pretty good but hard to compare to anything else. Coming from the original fiberglass which acoustically did nothing to this is obviously a substantial improvement. I havent yet done the firewall and front foot well areas as they will want 1 or more, but Im pleased with the ease of working with this product and weight.

glues in with weatherstrip adhesive or contact cement or cut it oversize and stuff it into a cavity. reduces sound in the 1/2 thickness pretty well.

Looks good. Haven’t installed it yet as I have other work to finish first. Seems very stout compared to he 60 year old deteriorated product that just vacuumed up.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Per the manufacturer, the booklet, "How To Soundproof Light Aircraft" has pertinent info about this. The question about the dB noise reduction rating isn't pertinent because the soundproofing foam we use in an aircraft is more absorption than having a Noise Reduction Coefficient (NRC). The booklets are available at no charge, part number 09-42755 and can be found in the "Accessories" tab of this web page.

Yes, and it has been added as PDF download to the "Documents" tab on this web page.

This material is priced and sold per linear foot.

The sheets are 4 ft wide.

Yes, as this is a foam type material. This should effectively adhere without a problem. Another option would be to use a contact cement as this would only be a 1 part vs. an epoxy being a 2 part.

The manufacturer does not have a recommended adhesive, but we do offer Pliobond, and spray adhesive like Thermo-Tec heavy duty spray adhesive which are used for soundproofing material. There are other adhesives you can review in our catalog or our web site.

This material was not designed to be painted, but it can be painted. A test sample would be recommended.

Yes, that is correct. You can use either Pliobond or a spray adhesive for the one that does not already have the adhesive with it.

It is spongy and will bend and form to curves easily.