Overview

|

**NOTE: Polyurethane and epoxy based paints require catalyst to cure which is not included. Order accordingly from "Accessories" tab. Enamel and waterborne polyurethane paints do NOT require catalyst.** Certification paperwork must be requested at time of order. If certs are required with purchase, please contact us by clicking here or calling sales. Products Techniques, Inc. manufactures its Specialty Polyurethane, Enamel, Epoxy and Waterborne Polyurethane Top Coats available in gloss, semi gloss and flat in our standard colors as well as the 595C Federal Color Standard. Also PTI will custom color match to your specifications upon request. To request a custom color match please fill out the custom request form (click here) and email it to PTI@ptipaint.com. Waterborne Polyurethane and Enamel top coats are available in aerosols, quarts and gallons. The two component Polyurethane and Epoxy top coats are available in quart kits and gallon kits. In addition, PTI will provide an aerosol kit for any of its two component Polyurethane and Epoxy top coats. The two component aerosol kit comes with a pump to add the catalyst prior to use. PTI will also provide material in smaller or large quantities than what is reflected on this page upon request. All of the coatings offered through Aircraft Spruce have been formulate to meet and exceed military, aviation and aerospace industry standards. Please refer to the Technical Data for each top coat to review product descriptions, mixing instructions, application instructions and to identify what coating will work best for your application. Before ordering solvents, reducers or primers please refer to the: PTI Touch Up Paint Kits Over many years, weather and UV rays degrade the gloss and condition of the original paints and coatings on your aircraft. Therefore it is best to match your Touch-Up Kit to the existing paint, as it is. We now offer small quantity touch up kits to fix minor imperfections to the paint job. Please click here for more information and to order a touch up kit.

|

Polyurethane

PT-799 POLYURETHANE TOPCOAT

PTI-PU SERIES

DESCRIPTION

PTI Polyurethane Series are high performance, two component polyurethane topcoats designed for exterior use onhigh performance general aviation, business jet, and commercial aircraft. This high performance coating is alsoused widely for industrial, oil & gas as well as original equipment manufacturing. PT-799 Polyurethane meets, andexceeds MIL-PRF-85285D Type I & II. These high performance coatings have excellent resistance to hydraulic jetfluid, fuel, crude oil, impact, salt and ultraviolet rays. PT-799 Polyurethane is extremely durable with excellentcolor and gloss retention.

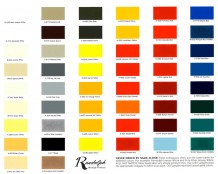

COLORS

This coating can be provided in any color & gloss range as designated by the Federal Standard 595C. Customcolors are also available.

COATING PROPERTIES & CHARACTERISTICS

| Mix Ratio, by volume | 1 part Base to 1 part Catalyst |

| Reducer | PT-1003 Type I |

| Recommended Dry Film Thickness | 1 mil |

| Admixed Viscosity | 12 - 15 seconds, max .4 Ford |

| Admixed Weight per Gallon | 10.2 lbs. |

| Admixed Solids By Weight | 65% |

| Theoretical Coverage | 600- 800 sq. ft.²/gal. |

| Pot Life | 4 hours |

| Coatings VOC | 340 g/L |

SHELF LIFE

Shelf life is only applicable for materials stored in unopened and undamaged original factory filled containers.1 year when stored between 50°-85° Fahrenheit.

MIXING INSTRUCTIONS

Shake component A in a paint shaker for 5 – 10 minutes for optimal results.

Admix by volume:

Add the Catalyst into the Base.1 Part Component A (Base)

1 Part Component B (Catalyst)

Admixed material should be allowed a 15-minute induction time for best application results.

Reduce: Use reducer PT-1003 Type II no more than 10% by volume.

- If using PTI additives to adjust the dry and cure times of the coating, please refer to those Product DataSheets for specific instructions for admixing the material.

APPLICATION

This product can be applied using conventional air spray equipment, HVLP spray system. Please consult with a PTIrepresentative for specific equipment recommendations and settings.

- Make sure pots, guns, and lines are purged and cleaned.

- Mix both base and catalyst thoroughly and filter/strain before spray application.

NOTE: It is not recommended to strain flat/matte coatings. - HVLP Spray Pressure: 7-10psi. Convention Equipment Spray Pressure 15-30psi

- Always air-blow and tack wipe the surfaces to be painted. Aircraft should be grounded to prevent static.

- Best application results: apply 3 coats: 1 fog/tack coat & 2 full coats from 0.6 – 1 mil thickness.

- Do not allow more than 48 hours to pass before applying the second coat.

- Recommended Dry Film Thickness is 1-2 mils. Some colors may require thicker films to achieve hiding.

- For wet sanding or buffing of coating, wait a minimum of 13 hours but not more than 26 hours.

NOTE: If paint is allowed to cure for more than 48 hours wet sanding and buffing is not possible.

NOTE: Application of PTI products requires the use of all OSHA approved safety equipment, including properventilation. Additionally, PTI products require the recommended temperature/humidity conditions and filmthickness ranges for optimal performance. The material, hangar, and aircraft skin temperatures should be no lowerthan 75° F / 25° C before, during and after application.

DRYING & CURING SCHEDULE

Dry times are based on the dry film thickness between 1-2 mils (25-50 microns).

Full chemical cure requires 7 days minimum.Air Dry Times(75°F / 25°C and 50% Relative Humidity)

Unaccelerated

12-15 hours

Accelerated (Using PTI PolyKick™)

30 minutes – 1 hour (see PolyKick™ Data Sheet)

Recoat Time:

1 hour or tack dry. You can recoat without sanding up to 72 hours after application.

Force Dry Times: 15 minutes at 225°F. Full chemical cure requires 2 hours at 225°F after the coating has dried hard.

EQUIPMENT CLEANUP

Use clean PT-1003 Type I Reducer. Do not allow material to dry or cure inside any equipment.

WET SANDING AND BUFFING RUNS AND/OR DRIPS

This coating will dry to an extremely hard but flexible finish. However, it can be wet sanded and buffed. For the best results wait a minimum of 13 hours but no more than 26 hours before wet sanding and buffing. PTI recommends that you use 600 grit wet sandpaper. If the paint cures for more than 48 hours wet sanding and buffing is not possible. If you are using the PTI additives "NO POP" or "NO PEEL" to slow the curing time, add four hours to the above times (a minimum of 17 hours but not longer than 30 hours). If you are using "PolyKick" to accelerate the dry time of this product, wet sanding

HEALTH, SAFETY, & STORAGE REQUIREMENTS

Refer to each individual material SDS (Safety Data Sheet) for specific requirements on the health, safety, storage

and handling requirements. Follow all local, state, and national regulations during surface preparation, material application and cleanup.

PRODUCT INFORMATION & DISCLAIMER

Product Data Sheets are periodically updated to reflect new information. It is important to use the latest and most

recent revision for the product being used. The foregoing information is accurate to the best of our knowledge. However, due to differences in customer handling, use and method of application which are not known and are beyond our control, Products Techniques, Inc. makes no warranties as to the end result.

Enamel

Enamel Topcoat

PTI Enamel Series

DESCRIPTION

PTI Enamels are high performance, single component enamel topcoats designed for interior or exterior use on high performance general aviation, business jet, and commercial aircraft. PTI Enamel meets, and exceeds TT-E-489G.These high performance coatings can be applied over wood, composite or metal surfaces. This product is available in bulk or in an aerosol can.

COLORS

This coating can be provided in any color & gloss range as designated by the Federal Standard 595C. Custom colors are also available.

COATING PROPERTIES & CHARACTERISTICS

| Flash Point | 45°F |

| Reducer | PTI-1022X66, PTI-1003 TYIII or Acetone |

| Primer | PTI Zinc Chromate Primer, Zinc Phosphate Primer or Zinc Oxide Primers |

| Recommended Dry Film Thickness | 1 mil |

| Weight (lbs per gallon) | 10 to 11 lbs |

| Theoretical Coverage | 350-400 sq. ft./gallon |

| Coatings VOC | Below 420 g/L |

SHELF LIFE

Shelf life is only applicable for materials stored in unopened and undamaged original factory filled containers. 1 year when stored between 50°-85° Fahrenheit.

MIXING INSTRUCTIONS

Shake component A in a paint shaker for 5 – 10 minutes for optimal results.

Reduce: Use reducer PTI-1022X66, PTI-1003 TYIII or Acetone Thinner.

- If Spraying: Thin 8 parts enamel with 1 part thinner.

- If Brushing: Thin 8 parts enamel with up to, but not more than 1 part thinner.

APPLICATION

This product can be applied by brushing on or using conventional air spray equipment, HVLP, Apollo Spray system. Please consult with a PTI representative for specific equipment recommendations and settings.

- Make sure pots, guns, and lines are purged and cleaned.

- Mix both base and thinner thoroughly and filter/strain before spray application.

NOTE: It is not recommended to strain flat/matte coatings. - HVLP Spray Pressure: 7-10psi

- Always air-blow and tack wipe the surfaces to be painted. Aircraft should be grounded to prevent static.

- Best application results: apply 2 coats: 1 fog/tack coat & 1 full coats from 0.6 – 1 mil thickness.

- Do not allow more than 48 hours to pass before applying the second coat.

- Recommended Dry Film Thickness is 1-2 mils. Some colors may require thicker films to achieve hiding.

DRYING & CURING SCHEDULE

Dry times are based on the dry film thickness between 1-2 mils (25-50 microns).

Air Dry Times (75°F / 25°C and 50% Relative Humidity)

Dries to touch in 1-2 hours; dries hard in 8-10 hours.

EQUIPMENT CLEANUP

Use clean PT-1022X66 Thinner. Do not allow material to dry or cure inside any equipment.

HEALTH, SAFETY, & STORAGE REQUIREMENTS

Refer to each individual material SDS (Safety Data Sheet) for specific requirements on the health, safety, storage and handling requirements. Follow all local, state, and national regulations during surface preparation, material application and cleanup.

PRODUCT INFORMATION & DISCLAIMER

Product Data Sheets are periodically updated to reflect new information. It is important to use the latest and most recent revision for the product being used. The foregoing information is accurate to the best of our knowledge. However, due to differences in customer handling, use and method of application which are not known and are beyond our control, Products Techniques, Inc. makes no warranties as to the end result.

Epoxy Topcoat

LOW VOC EPOXY TOPCOAT

PTI-EP SERIES

DESCRIPTION

PTI Epoxy Series are high performance, two component catalyst cure epoxy topcoats designed for interior andexterior use on high performance aviation/aerospace, industrial, and marine applications. PTI Epoxy meets, andexceeds MIL-PRF-22750E&F Type I as well as BMS 10-11V Type II. This high performance coating providesultimate protection. These epoxy topcoats provide a high quality finish to metal, wood and most other materialscapable of being coated and offer excellent chemical resistance properties.

COLORS

This coating can be provided in any color & gloss range as designated by the Federal Standard 595C. Customcolors are also available.

COATING PROPERTIES & CHARACTERISTICS

| Mix Ratio, by volume | 2 parts Base to 1 part Catalyst |

| Reducer | PT-1003 Type II |

| Recommended Dry Film Thickness | 1 to 2 mils |

| Admixed Viscosity | 17 seconds, max #4 Ford |

| Admixed Weight per Gallon | 8.45 lbs. |

| Admixed Solids By Weight | 67% |

| Theoretical Coverage Per Gallon | 600 square ft. at 1 mil thickness |

| Pot Life | 4-6 hours |

| Coatings VOC | 340 g/L |

SHELF LIFE

Shelf life is only applicable for materials stored in unopened and undamaged original factory filled containers.1 year when stored between 50°-85° Fahrenheit.

MIXING INSTRUCTIONS

Shake component A in a paint shaker for 5 – 10 minutes for optimal results.

Admix by volume:

2 Part Component A (Base)Add the Catalyst into the Base.

1 Part Component B (Catalyst)

Admixed material should be allowed a 15-minute induction time for best application results.

Reduce: Use reducer PT-1003 Type II no more than 10% by volume.

APPLICATION

This product can be applied by brushing, rolling or using conventional air spray equipment, HVLP spray system. Please consult with a PTI representative for specific equipment recommendations and settings.

- Make sure pots, guns, and lines are purged and cleaned.

- Mix both base and catalyst thoroughly and filter/strain before spray application.

NOTE: It is not recommended to strain flat/matte coatings. - HVLP Spray Pressure: 7-10psi. Conventional Spray Pressure 15-30psi

- Always air-blow and tack wipe the surfaces to be painted. Aircraft should be grounded to prevent static.

- Best application results: apply 3 coats: 1 fog/tack coat & 2 full coats from 0.6 – 1 mil thickness.

- Do not allow more than 48 hours to pass before applying the second coat.

- Recommended Dry Film Thickness is 1-2 mils. Some colors may require thicker films to achieve hiding.

- For wet sanding or buffing of coating, wait a minimum of 13 hours but not more than 26 hours.

NOTE: If paint is allowed to cure for more than 48 hours wet sanding and buffing is not possible.

ventilation. Additionally, PTI products require the recommended temperature/humidity conditions and film

thickness ranges for optimal performance. The material, hangar, and aircraft skin temperatures should be no lower than 75°F / 25° C before, during and after application.

DRYING & CURING SCHEDULE

Dry times are based on the dry film thickness between 1-2 mils (25-50 microns).

Air Dry Times (75°F / 25°C and 50% Relative Humidity)

Set to touch: 4 hours

Dry hard: 8 hours

Full chemical: 7 days minimum

Force Dry Times: MUST AIR DRY FOR AT LEAST 15 MINUTES.

Dry hard: 2 hours at 150°F.

Full chemical: After “dry hard” 2 hours at 225°F

EQUIPMENT CLEANUP

Use clean PT-1003 Type II Reducer. Do not allow material to dry or cure inside any equipment.

HEALTH, SAFETY, & STORAGE REQUIREMENTS

Refer to each individual material SDS (Safety Data Sheet) for specific requirements on the health, safety, storage and handling requirements. Follow all local, state, and national regulations during surface preparation, material application and cleanup.

PRODUCT INFORMATION & DISCLAIMER

Product Data Sheets are periodically updated to reflect new information. It is important to use the latest and most recent revision for the product being used. The foregoing information is accurate to the best of our knowledge. However, due to differences in customer handling, use and method of application which are not known and are beyond our control, Products Techniques, Inc. makes no warranties as to the end result.

Waterborne Poly

WATER BORNE POLYURETHANE TOPCOAT

PTI-WBP SERIES

DESCRIPTION

PTI Water Borne Polyurethane is a high performance, single component topcoat designed for interior or exterioruse on high performance general aviation, business jet, and commercial aircraft. PTI Waterborne Polyurethane is anexcellent coating to apply over both metal and composite substrates. This product is available in bulk and aerosol

COLORS

This coating can be provided in any color & gloss range as designated by the Federal Standard 595C. Customcolors are also available.

COATING PROPERTIES & CHARACTERISTICS

| Flash Point | 76°F |

| Reducer | Distilled Water |

| Primer | PTI-WREP |

| Recommended Dry Film Thickness | 1 mil |

| Weight (lbs per gallon) | 9 to 11 lbs |

| Theoretical Coverage | 350-400 sq. ft./gallon |

| Coatings VOC | Below 70 g/L |

SHELF LIFE

Shelf life is only applicable for materials stored in unopened and undamaged original factory filled containers.1 year when stored between 50°-85° Fahrenheit.

MIXING INSTRUCTIONS

Shake component A in a paint shaker for 5 – 10 minutes for optimal results.

Reduce: Use distilled water to thin this product.

If Spraying: Thin 10 parts paint with 1 part water.

If Brushing: DO NOT THIN.

APPLICATION

This product can be applied by brushing on or using conventional air spray equipment, HVLP, Apollo Spray system.Please consult with a PTI representative for specific equipment recommendations and settings.

- Make sure pots, guns, and lines are purged and cleaned.

- Mix both paint and water thoroughly and filter/strain before spray application.

NOTE: It is not recommended to strain flat/matte coatings. - HVLP Spray Pressure: 7-10psi

- Always air-blow and tack wipe the surfaces to be painted. Aircraft should be grounded to prevent static.

- Best application results: apply 2 coats: 1 fog/tack coat & 1 full coats from 0.6 – 1 mil thickness.

- Do not allow more than 12 hours to pass before applying the second coat.

- Recommended Dry Film Thickness is 1-2 mils. Some colors may require thicker films to achieve hiding.

NOTE: Application of PTI products requires the use of all OSHA approved safety equipment, including properventilation. Additionally, PTI products require the recommended temperature/humidity conditions and filmthickness ranges for optimal performance. The material, hangar, and aircraft skin temperatures should be no lowerthan 75° F / 25° C before, during and after application.

DRYING & CURING SCHEDULE

Dry times are based on the dry film thickness between 1-2 mils (25-50 microns).

Air Dry Times(75°F / 25°C and 50% Relative Humidity)

Dries hard in 40 minutes; full cure in 24 hours..

Force Dry Times: 15 minutes at 225°F. Full chemical cure requires 2 hours at 225°F after the coating has dried hard.

EQUIPMENT CLEANUP

Use clean water. Do not allow material to dry or cure inside any equipment.

HEALTH, SAFETY, & STORAGE REQUIREMENTS

Refer to each individual material SDS (Safety Data Sheet) for specific requirements on the health, safety, storageand handling requirements. Follow all local, state, and national regulations during surface preparation, materialapplication and cleanup.

PRODUCT INFORMATION & DISCLAIMER

Product Data Sheets are periodically updated to reflect new information. It is important to use the latest and mostrecent revision for the product being used. The foregoing information is accurate to the best of our knowledge.However, due to differences in customer handling, use and method of application which are not known and arebeyond our control, Products Techniques, Inc. makes no warranties as to the end result.

Reviews

It was not white, but an off white. The can expired in 2019. I will never purchase that brand again. Totally unusable.

SOCOGLAZE ENAMEL FLAT INSIGNIA WHITE AEROSOL

Good paint but put in a cheap spray can

SOCOGLAZE ENAMEL GLOSS INSIGNIA WHITE AEROSOL

There has been reviews stating this paint did not dry hard after 48 hours. For me the paint dried hard on my first check after 16 hours. It may have been dry prior to that. It worked very well and provided a smooth glossy surface. I was surprised how smooth and glossy it dried.

This review covers PT-799: Excellent erosion and solvent resistance. Weve found this coating to also be suitable for application over flexible surfaces such as moulded foam rubber, without exhibiting surface cracking when deformed. Id agree with the reviewer that stated that insignia white was slightly cream colored, however I think youd only notice the difference if comparing to a pure TiO2 white. Without a true white reference, it appears about as white as your eyes can discern.

Great product, just want to mention, they tell you the lead time is 2 weeks, when I ordered it, it took a month.

Agree with Darren R, drying time way to long. 48 hrs still tacky in 95° temperatures! Brought job into A/C & another 24 to dry. Was still soft for another 48+ hrs. Have used PTI for wing tips several years ago without any problems . Then dried hard over night. Pre 2005 paint dried faster. Consulted paint expert says rattle canss dont have enough hardener in the paint so it will take longer drying and hardening time. He recommended another mfg. product their paint shop uses.

Plastic lid on can was damaged in shipment. Paint OK The green paper packaging instead of plastic pellets is resulting in shipping damage on all your paint products in cans.

This is advertised as their brightest white. Upon delivery and test spray, it was almost a cream color. Couldnt even call it a shade of white, let alone their brightest. The can is stamped Insignia, but I wonder if they filled it with another color by mistake. I emailed the manufacturer and aircraft spruce both. Only spruce got back to me and said Insignia is typically the whitest bright offered, but it can vary by manufacturers. Still waiting on a response from PTI. I guess no one has heard of Matterhorn White. Unimpressed.

I had a bad experience with the PTI Enamel paint. The drying times are not even close to what they say -the paint took nearly 3 times longer to dry. The paint was soft even weeks later. Very disappointed with the quality of this paint.

Followed directions for epoxy topcoat exactly and got lousy results. For flat paint they recommend you dont strain it--ignore that unless you want little particles. Also ignore the pressure they state for HVLP guns--7-10 psi is *way* too low. After experimenting I got tolerable results with ~20 psi, but the coverage is poor to fair (this paint is very thin/watery) and the finish isnt flat, its satin at best. I had much better results with Stewart Systems, so Ill be going back to them from now on.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

It depends on the material. For the polyurethane, since it needs the catalyst, a one quart kit yields 2 quarts of material. For the waterborne and enamel products, a one quart kit will yield one quart of material.

You would need to use a dust/mist respirator protective mask with the use of waterborne polyurethane.

Our topcoats are compatible with that primer and most any other primer. However, for best results we recommend you use our epoxy primer as it is specifically formulated to work with our topcoats.

The quantities in the frequently asked questions does include the catalyst. So 3 to 4 gallons of mixed paint.

The paint that you would want to use is the Polyurethane. As for the amount, you need we would need to know the size of the area you are trying to paint. 1 gallon (128 oz per gallon) of the polyurethane should cover 600 sq ft at 1 mil thickness. Also, if you are covering bare aluminum you will need to first prime the surface with our epoxy primer.

Yes you can use adhesives with MEK in them on the Polyurethane topcoat. Please wait two weeks before doing so. Even when polyurethanes and even epoxies for that matter dry hard it does not mean they are fully cured. To have peak chemical resistance the coating must be cured.

It is always best to discuss paint types with a professional painter, but polyurethane is commonly used for both exterior and interior applications.

It is 2 parts. One part paint, one part catalyst.

Yes, you can use both, but it recommended to use the minimum allowed amount of each product.

The mix ratio is indeed a 1:1 for polyurethane. Polyurethane and epoxy prop coat require catalyst. We have fixed our note in overview to only reference the catalyst requirement. The mix ratios for each type are defined further down the page now.