Overview

|

The Apex series, fully ground adjustable hubs are the finest crafted hubs available to the ultralight and experimental market. Made in-house on our new Haas VF4 CNC vertical milling station, these hubs offer features that are unavailable on other hubs. By nature of the fact that Powerfin own the machine, and can take the time to pack features into these hubs that couldn’t afford to buy from an outside vendor. They are highly sculpted solid 6061-T6 aluminum and are made to the finest CNC machining tolerances in the industry. In fact, Powerfin specifically designed the machining process to insure a perfectly balanced prop hub. The hubs are anodized to a luxurious black finish you will be proud to display.

The multi-blade configurations offered with the Apex hubs allow us to take advantage of the large reduction ratios offered by Rotax and Hirth in their gearboxes. Also, more horsepower can be loaded into more blades so this may be a solution to some applications that have limited room to turn a propeller. |

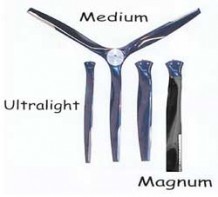

Models

The blade finish of POWERFIN Propellers rivals anything this industry has yet produced. There are UV inhibitors mixed into the materials used so your propeller will stay shiny for years. Also include instructions for maintaining the finish against deterioration. Every POWERFIN blade leaves the factory with urethane leading edge tape applied to it.

Every aspect of POWERFIN Propellers exemplifies a precision made product. The use of PRE-PREG carbon fiber and e-glass results in blades that are all molded to within 5-grams total weight of each other. Due to this extremely tight process, POWERFIN can easily match the balance of a needed replacement blade by referencing the number scribed onto each blade's root.

Model "B" blade

The 'B' model is a general use propeller blade, although specifically designed to run on significantly smaller diameters than most other props. The Model-B runs very well on a 582/2.58 as a three blade 60" for example, and can out-produce our competition even when running much smaller diameters.

Diameter Range: Minimum: 48" <> Maximum 65"Speed Range: 22 - 95 knots / 25 - 110 mph

Model "C" blade

The 'C' model is designed specifically for powered parachutes as a three blade 64" on a Rotax 582/2.58. This design works well on Rotax 447's through Rotax 618 as well as the Hirth engines that fall between 40 and 80 horsepower. This has been the propeller being sold as standard equipment on 6 of the top 7 PPC's.

DDiameter Range: Minimum: 48" <> Maximum 65"Speed Range: upto 31-knots / 35-mph

Model "E" blade

The 'E' model is our smallest, narrowest propeller blade - designed for engines between 15 and 30 horsepower. Backpack & PPC's are the target of this design although the blade has been proven very efficient on many older, fixed wing airplanes with diameter restrictions. This is the ONLY pitch adjustable prop available to backpack units.

Diameter Range: Minimum: 39" <> Maximum 53"Speed Range: 20 - 70 knots / 22 - 80 mph

Model "F" blade

The 'F' model is our largest propeller - designed for larger two-stroke engines that use the higher gear reduction ratios and horsepower up to 115. This prop blade runs beautifully on a Rotax 503/3.47 as a three blade 66" to 70". A two place Kolb can't squeeze any more efficiency out of a 503/3.47 than with our F-model 68" prop. This prop is also the finest prop available for the Rotax 912, 912S, and 914 engines.

Diameter Range: Minimum: 48" <> Maximum 75"Speed Range: 22 - 95 knots / 25 - 110 mph

Documents

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.