| Type | Part No. | Thread Size | Cotter Pin Size | Price | Buy |

|---|---|---|---|---|---|

| Cad Plated | AN320-3 | 10-32 | AN380-2-2 | $0.93 | |

| Cad Plated | AN320-4 | 1/4-28 | $1.16 | ||

| Cad Plated | AN320-5 | 5/16-24 | $1.25 | ||

| Cad Plated | AN320-6 | 3/8-24 | AN380-3-3 | $1.99 | |

| Cad Plated | AN320-7 | 7/16-20 | $1.47 | ||

| Cad Plated | AN320-8 | 1/2-20 | $2.27 | ||

| Cad Plated | AN320-9 | 9/16-18 | AN380-4-4 | $3.35 | |

| Cad Plated | AN320-10 | 5/8-18 | $4.35 | ||

| Cad Plated | AN320-12 | 3/4-16 | AN380-4-5 | $4.35 | |

| Stainless Steel | AN320C3 | 10-32 | AN380-2-2 | $1.10 | |

| Stainless Steel | AN320C4 | 1/4-28 | $1.52 | ||

| Stainless Steel | AN320C5 | 5/16-18 | $1.69 | ||

| Stainless Steel | AN320C6 | 3/8-24 | AN380-3-3 | $2.31 | |

| Stainless Steel | AN320C7 | 7/16-20 | $4.85 | ||

| Stainless Steel | AN320C8 | 1/2-20 | $3.75 | ||

| Stainless Steel | AN320C10 | 5/8-18 | $9.50 | ||

| Stainless Steel | AN320C12 | 3/4-16 | AN380-4-5 | $8.50 |

Overview

|

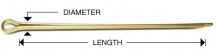

Fabricated from steel and cadmium plated per QQ-P-416A, Type II, Class 3. AN310 castle nuts are used with drilled-shank bolts, clevis bolts, eye bolts and studs. The slots in the nut accommodate a cotter pin for safety purposes. The thinner AN320 castellated shear nut, with half the tensile rating of the AN310 nut, is used with clevis bolts and threaded taper pins which are subject to shearing stress only.

Less 20% for quantity 100/Part No. |

Reviews

NUT, SHEAR AN320-7

Great nut!

NUT, SHEAR AN320-10

Great for using with the AN3-6 bolts to hold those pin things and keeping the whole thing (Trim Tab in this case) from falling apart. Two thumbs up!

NUT, SHEAR AN320-3

All the nuts worked as designed with no defects. Thanks for the quick reimbursements on the AN310 nuts ordered by mistake. ACS is a great company. Jim has a reason to be proud of his staff!

The right side thanks

No problems, no hassles. Easy transaction. Quality parts.

Highest quality, great service, fast shipping & excellent prices

Fit exactly where we needed it.

its a nut..... it works for me

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.